Top 5 Trusted BIW Fixture Design in India

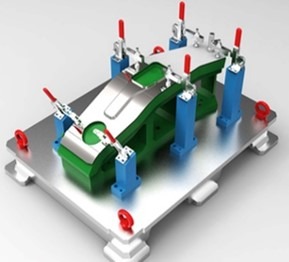

Overview of BIW Fixture Design

Advance Mechanical Services provides reliable BIW fixture Design for the automotive industry in India. As a ZED Gold Certified engineering company, we specialize in designing welding fixtures, checking gauges, and prototype jigs that help OEMs meet demanding quality standards and improve production efficiency.

Our capabilities include advanced simulation tools like Process Simulate, Robcad, Delmia, and discrete event simulation to optimize cycle times and robot motion. We also design and build turnkey BIW automation systems that integrate seamlessly into your manufacturing process.

Key Benefits of Our BIW Fixture Design

At Advance Mechanical Services, we know that every automotive manufacturer faces unique challenges. Our BIW fixture Design help you solve these challenges with reliable, precision-engineered tools. By integrating cutting-edge CAD/CAE technology, digital manufacturing simulation, and robust testing methods, we ensure each fixture meets stringent quality and safety standards.

With our expertise, clients achieve faster cycle times, reduced downtime, and improved weld accuracy. Our solutions support everything from complex robotic welding cells to manual workstations, providing flexibility for different production scales and requirements.

Beyond design and build, our team offers complete process validation services. We work closely with your engineers to validate tool designs, robot paths, and cycle time simulations before implementation. This proactive approach helps avoid costly rework and production delays, ensuring a smoother launch for new vehicle models.

Industries We Serve

While our primary focus is the automotive sector, our BIW fixture Design are equally valuable in aerospace, heavy equipment, and industrial machinery manufacturing. Industries that demand high repeatability, precision welding, and tight tolerances rely on our engineering expertise to deliver consistent results.

As a trusted partner to several global OEMs and Tier 1 suppliers, Advance Mechanical Services has built a reputation for innovation, reliability, and engineering excellence. By choosing our BIW fixture Design, you benefit from a team committed to delivering quality, speed, and cost-effectiveness in every project.

Why BIW Fixture Design Matter

Modern automotive manufacturing relies on precision. Our BIW fixture Design ensure accurate weld placement, reduced cycle times, and lower rework rates. With years of expertise in CAD/CAE, ergonomic studies, and robot programming, we help customers like BMW, Daimler, Ford, and VW achieve consistent quality at scale. By using simulation-driven design, we predict and resolve issues before physical build, saving time and cost.

In addition, our engineering team handles line balancing and process optimization to ensure your BIW production meets OEM targets. Learn how ABB Robotics technology helps us build smarter, faster, and more flexible welding lines.

Frequently Asked Questions

What industries use BIW fixture Design ?

Mainly automotive OEMs and Tier 1 suppliers, but also aerospace and heavy machinery manufacturers who need precise assembly tooling.

Does Advance Mechanical Services deliver turnkey systems?

Yes, we design, build, install, and validate complete BIW automation lines and robotic welding cells.

What simulation tools do you use?

We work with Process Simulate, Robcad, Delmia, and other advanced software to model robot motion, cycle times, and process flows.

Get Started Today

Ready to enhance your BIW production? Contact Advance Mechanical Services now and explore how our BIW fixture Design can boost accuracy, efficiency, and quality for your automotive manufacturing.