Our BIW Solutions

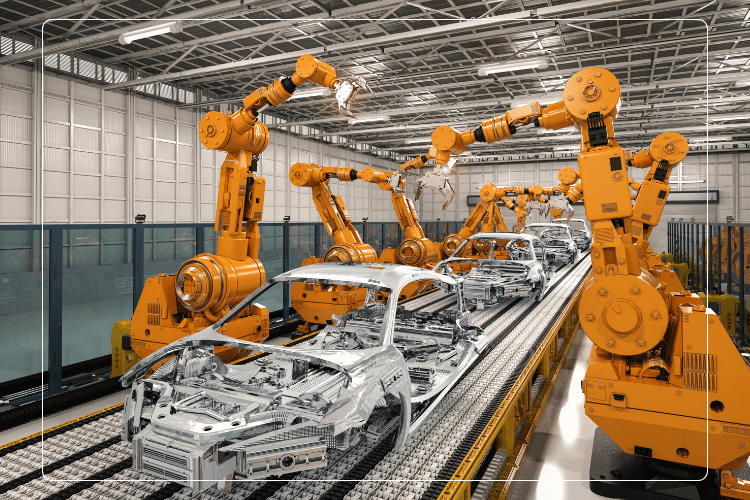

One of our core businesses is the production of fully automated bodyshell lines for all vehicle body parts. Our product portfolio includes the initial conceptual design of the equipment in the course of an SE examination and the development of a plant concept, taking all customer-specific requirements and boundary conditions into consideration.

Automotive Body shop Engineering capabilities include BIW Tooling, Fixture Design, Digital Manufacturing, Discrete Event Simulation, Ergonomic Analysis, Factory Layout and Documentation for various OEM standards including GM, Daimler, BMW, VW, FORD, Audi and Volvo.

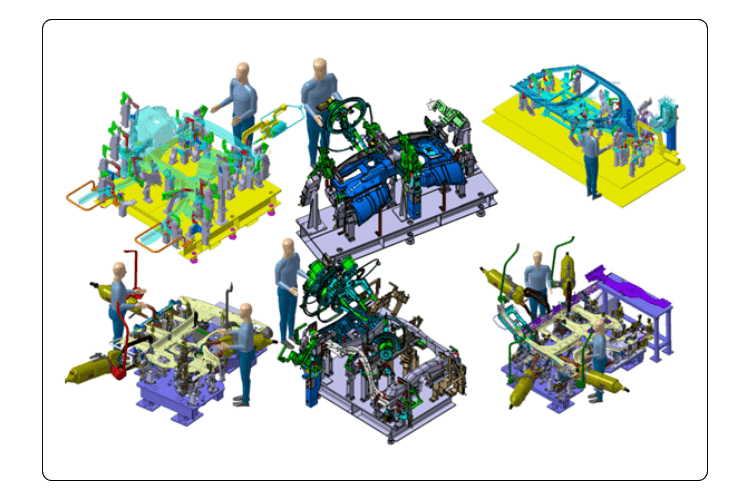

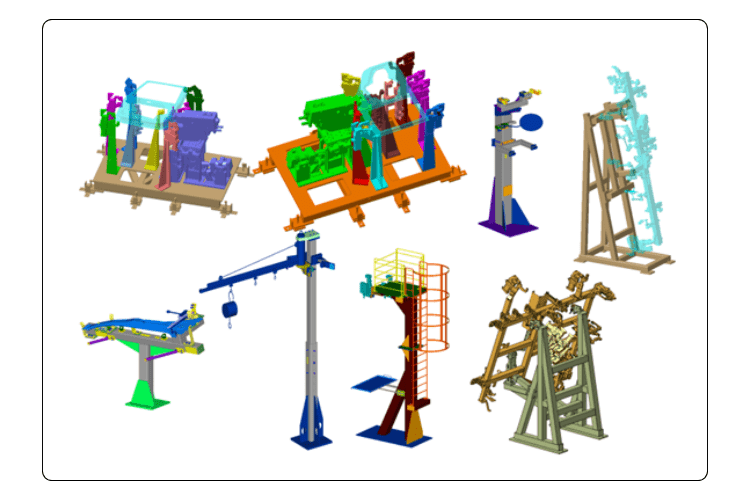

Automotive Tool Design capabilities include design of various tools such as Load Fixtures, Geometry Fixtures, Re-Spot Fixtures, Passing Tables, Racks, Trunnion Fixtures, PED Welders, Gun Stand, Glue Stands, Gripper Stands, Stud, Nut Welders, Grippers, Assembly Fixtures, Roller Hemming Fixtures, Hand Tools, Checking Fixtures, Framing Station Fixtures, Conveyor Pallets, Part Hangers, Curing Tools, Pull-off Carts, Laser Application Fixtures, including fixtures for some Special Applications such as Piercing Units, Manual Hoists for various Applications such as Spot Welding, Arc Welding, Laser Welding, Stud/Nut Welding, Roller Hemming, Gluing, Material Handling, Machine Tending, Press Automation and for Curing, Clinching and Measuring applications.

In the area of semi-automated and manual joining machines, we exact special requirements regarding the overall ergonomics (loading, welding, unloading) machine operator workload and safety.

Our joining devices are developed according to the individual customer specifications. Our engineers draw on their wealth of experience as well as an extensive component library of standard components, in order to facilitate efficient design and, simultaneously, profitable manufacturing.

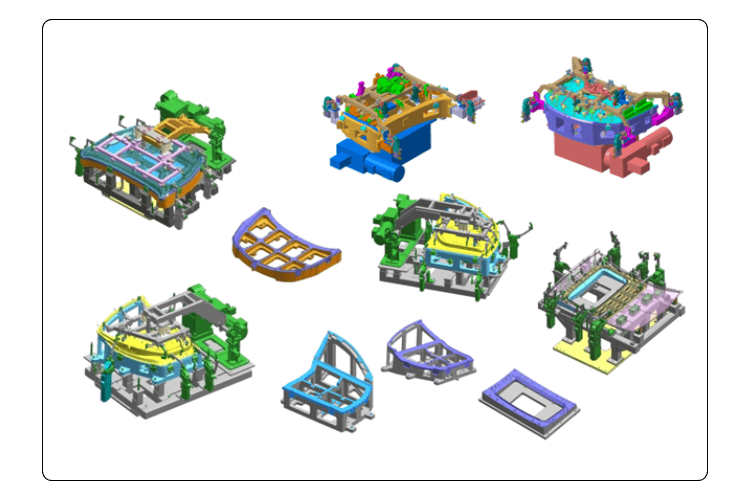

The joining of sheets can be done in different ways. In addition to bonding and welding techniques, the folding technique has proven itself in body construction. Whatever your goal, we offer you a comprehensive range of strategies to optimize your production and product.

The roller hemming system consists of a robot, which folds down the flange of the component with the help of a roller folding head, and a clamping fixture with the corresponding hold-down clamps.

The prefixing system (Preclincher) is a feeder tool for the table-top folding system. It is used to fold the flange to approx. 90° at critical positions.

With an automated table-top system, movement is carried out by electro-mechanical components. This technology guarantees a high level of process safety as well as low cycle times and a low space requirement.

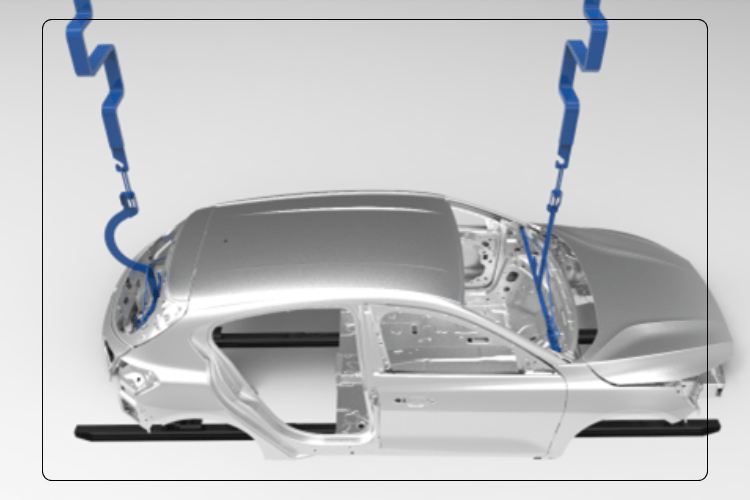

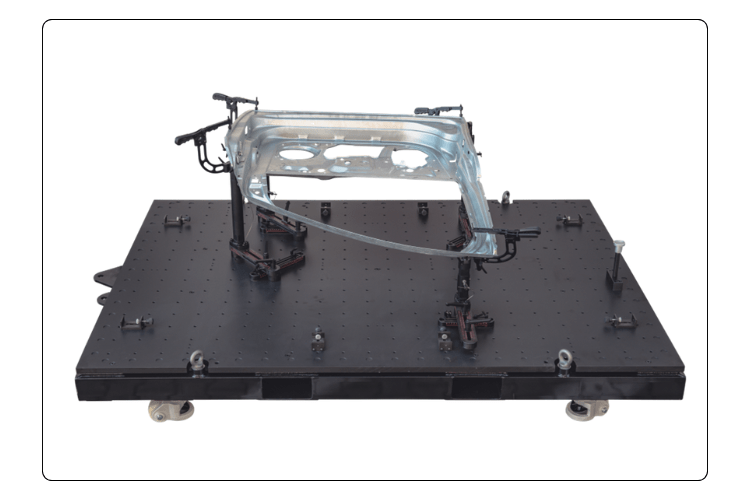

Advance Mechanical Services develops and provides you with all types of auxiliary tools, developed according to your individual specifications, in order to ensure that the moveable add-on parts are held in a defined position during the coating process.

Furthermore, load carrying devices and carriage systems, which are used to transport the bodyshell through immersion baths as well as through the entire coating process, are among the areas of expertise we have built up over the years as automation specialist. Equipment for mounting the rear sliding doors to take a chassis without a B pillar or hinges through the painting process can be provided.

Measurement and inspection concepts for pressed parts as well as the fusion process of vehicle body parts are developed in close collaboration with our customers and in accordance with their various requirements. Thanks to our extensive experience and own patents, we are able to offer the whole spectrum, from the concept phase to production and final commissioning on-site.

- Preparation of the overall measuring concept

- Definition of the measuring and inspection points

- Definition of the positioning points

- Compilation of the measuring software

- Production of all components

- Complete assembly

- 3D measuring & documentation

- Nominal scanning & documentation

- On-site commissioning

- Recertification

- Manuals

- Patented AUT-TECH clamping systems for gauge construction with standard components

- Matching fixture:Gauge for simulation of the assembly process and visual inspection of all closure parts.

- Stamping gauge: Gauge for locating and measuring of individual sheet metal parts. Patented AUT-TECH tensioning system for the manufacturing of fixtures with standard components.

- Ring gauge: Gauge for the visual control of complete doors, hoods and lift gates (closures).

- Individual gauge: Gauge for individual requirements after customer request

- Opening plug:Gauge for visual inspection of the openings of doors, hoods, etc. at car body

- Holding fixture:Device for locating of individual components or complete assemblies on a measuring machine

We have been substantiating the AUT-TECH standards of quality, flexibility and innovation in the automotive sector for decades. We have also expanded our areas of expertise to other future-oriented industries such as the aviation industry, the pharmaceutical sector and special purpose vehicle engineering.

Complex production requires many customized special tools. This is why we offer our long time partners all the necessary manufacturing and machining tools, transportation devices, welding fixtures, mounting equipment and measurement gauges.

- Underbody light truck

- Particle filter truck

- Driver cabin field chopper

- For separating a body side for spare part production

- For a cutter head of a field chopper

- For subassemblies of the driver cabin for a field chopper

Advance Mechanical Services offers automation solutions for majority of the applications in various industry segments. Our competitive and high productive solutions emerge from a strong focus on productivity improvement. The most profitable production concepts emanate from a close co-operation with the end user. While the customer possesses knowledge about his products and processes, Advance Mechanical Services can add value by providing flexible automation and robotic application skills and experiences to ensure the customer problems are resolved.

- SPOT WELDING

- ARC WELDING

- LASER WELDING

- STUD/NUT WELDING

- ROLLER HEMMING

- DISPENSING

- MACHINE TENDING

- PRESS AUTOMATION

- CURING

- CLINCHING

- MEASURING

- 3D PRINTING

- PICK PACK AND PALLETISE