About Robotic LWAM

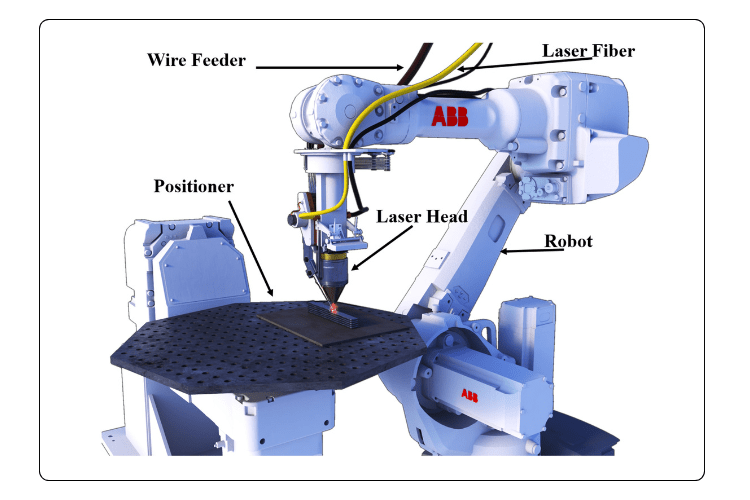

Laser Wire Arc Additive Manufacturing (LWAM) is an additive manufacturing process that utilizes a laser arc as the heat source to melt a metal wire, which is deposited layer by layer to build up a 3D object.

The LWAM Robotic Cell combines the robustness and agility of the ABB IRB-1200 Robot with the advanced capabilities of Robot Studio software, providing users with intuitive control and seamless integration for precise and efficient operation integrated with a unique patented Laser Head which focuses a maximum of 4.5KW of Laser energy to melt the metal and a wire feeder to deposit the wire in a pre-programmed path to make components.

- Wire Feedstock:An open source metal wire, typically made of materials like, aluminum, steel, or Inconel, is used as the raw material for the process.

- Laser:4.5KW Laser power source generates the Laser, fed to the metal through a laser gun is used to melt the wire.

- Motion Control System:The wire feedstock and the patented laser head is precisely moved by the 6 Axes Robot as per the program to form the part layer by layer.

- Cooling: The water chiller Unit of 6KW is used to cool the laser power source and the laser heads for continuous operation.

- Provides outstanding performance by utilizing ABB’s superior path performance and Absolute Accuracy calibration

- Robot’s close motion coordination with an external axis

- Seamless integration with the robot controller and suitable welding equipment

- High power laser, energy efficiency and consistent performance.

- Advanced technology reduces defects and post-weld processing.

- Flexible setup for different materials and welding techniques.

- Robust design suitable for industrial environments.

- Cost-Effective:Compared to other additive manufacturing methods, LWAM uses inexpensive materials and equipment, making it a more affordable solution for large-scale parts.

- High Material Utilization: LWAM offers high material efficiency because it uses a wire feed, minimizing waste compared to powder-based methods.

- Scalability: It is suitable for producing large parts, unlike many other AM processes that are restricted to smaller components.

- Versatility in Materials: LWAM can handle a wide range of metals, making it highly adaptable for various industries.

- Reduced Lead Time: Large parts can be manufactured much faster than traditional machining methods.

- Aerospace: Manufacturing complex, lightweight structures like brackets, frames, or engine components.

- Marine: Producing large, durable parts that can withstand harsh environments.

- Automotive: Creating high-strength components with intricate geometries.

- Tooling: Fabricating large custom tools and dies for industrial use.

Video

Advance Hyrel3D Printer

Reliability is our core values

It’s simple: We believe in making things that will work for a long time. that is what we had in mind when we designed the advance hyrel3d system. we chose an all-metal design because lesser parts fail. we wanted a machine that would be at home in a laboratory, a classroom, an office, or on the floor of a manufacturing plant.

- Flexibility

- Customize the machine to suit customer needs

- 60 different extruders to support.

- 6 axis control system to make plastics, metals, resins, ceramics & gels.

3D Printing is changing the world

“For those of you who believe that 3D printing is just a fringe technology overhyped by an enthusiastic maker community, or that its impact is limited to headline grabbing futuristic experiments like 3D printed organs, think again. Industrial 3D printing, also referred to as additive manufacturing, is poised to significantly and permanently disrupt global production. No longer just a tool for rapid prototyping, 3D printing is now being used for end-use part production and adoption is growing exponentially.”

Advance Hyrel3D Systems are capable of printing thousands of materials. the only limitation is your imagination.

Advance Hyrel3D is proud to have some of the most imaginative, innovative customers in the world. our systems are being used by thought leaders in the fields of biology, medicine, engineering, and education to do incredible things. we make sure they always have the perfect tools at their disposal for their needs.

Advance Hyrel 3D Printers

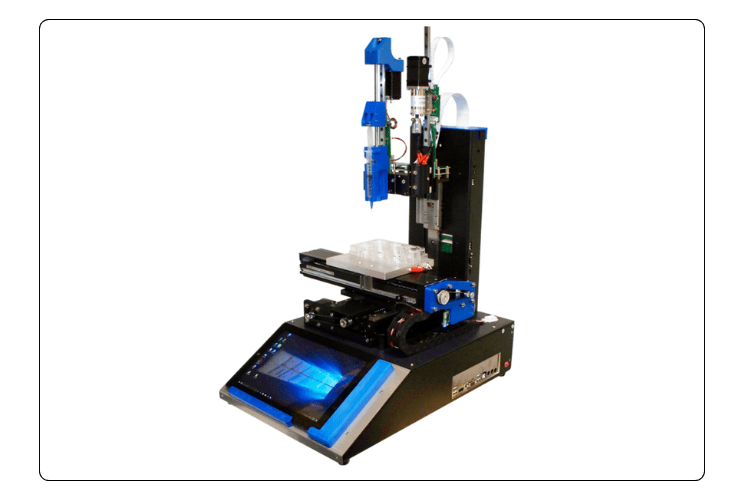

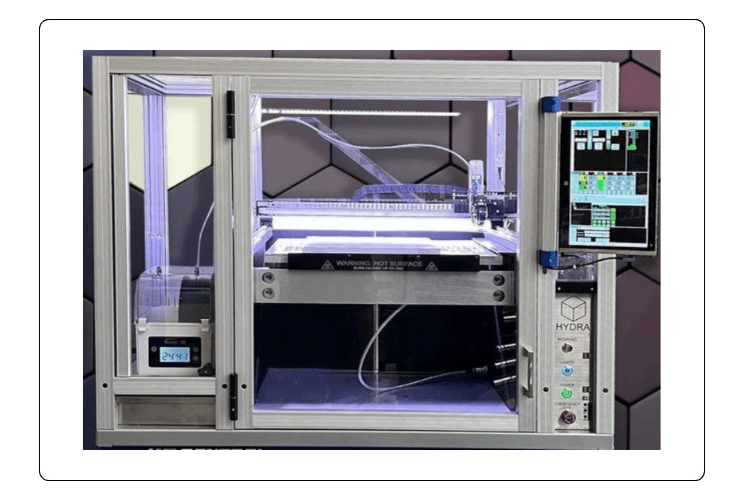

HYDRA 21 – RUGGED ALL METAL BENCHTOP FOR THE LABORATORY

Ideal for

- Multiple material prints

- Plug-and-play modular heads

- Working with with large volume extruders

- Circuit board milling, drilling, laser engraving

Specifications in X,Y,Z

- 400x300x250 mm

- 6x6x1 micron positional resolution

- 60x60x10 microns positional accuracy

- Recommended print speed upto 2000 mm/min

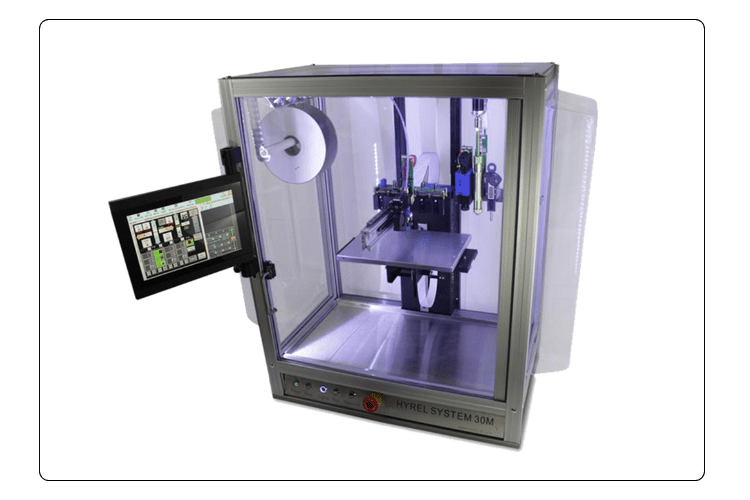

HYDRA 16A – RUGGED LARGE VOLUME PRINTER FOR VARIOUS MATERIALS

Ideal for

- Very large scale prints

- Multiple material prints

- Plug-and-play modular heads

- Working with with large volume extruders

- Circuit board milling, drilling, laser engraving

Specifications in X,Y,Z

- 400x300x250 mm

- 600x400x250 mm

- 600x400x500 mm

- 6x6x1 micron positional resolution

- 60x60x10 microns positional accuracy

- Recommended print speed upto 2000 mm/min