MTCM Edge Module

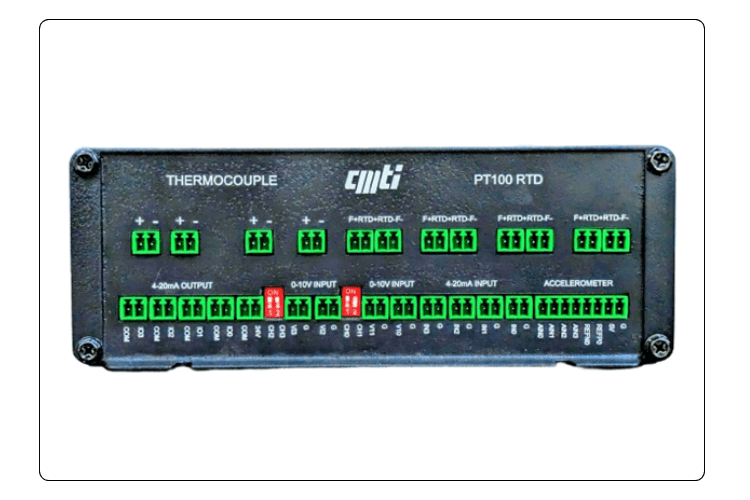

Advance Mechanical Services India has developed a proprietary Machine tool condition monitoring (MTCM) EDGE module in collaboration with Central Manufacturing Technology Institute (CMTI). These kits are economical as they communicate via OPCUA Server thereby eliminating the need for hardware for data transmission.

Machine tool condition monitoring (MTCM) EDGE module supports condition monitoring of machine tools. Various sensors and meters can be installed to measure multiple parameters such as temperature, vibration, and energy.

These sensors can generate vast amounts of data, which can be analyzed using algorithms to detect patterns and anomalies that indicate potential problems. The FFT analysis can be performed at the edge to monitor the vibration level at the spindle during the machining process to detect anomalies. Edge computing devices can communicate with a central server/cloud server to transfer relevant data/results. Overall, the Machine tool condition monitoring EDGE module for condition monitoring of machine tools can provide real-time insights into the performance and health of the machines, enabling proactive maintenance and reducing downtime and repair costs.

Machine tool condition monitoring EDGE module consists of 3 Sub Modules (stackable)

- 1. Energy Monitoring and Analysis Module – EMAM

- 2. Vibration Monitoring Module (Non-IEPC) – VMM

- 3. Temperature Monitoring Module — TMM

Machine tool condition monitoring EDGE module is cost-effective and affordable solution for SMEs for Condition Monitoring of Machine tools

- 1. ARM Dual core processor (32-bit) that runs at 160MHz to 240MHz

- 2. SPI/12C/UART protocols

- 3. CAN, Ethernet MAC Interface

- 4. Inbuilt Wi-Fi to monitor devices remotely.

- 5. Inbuilt Wi-Fi to monitor MODBUS protocol 12-bit ADC..

- 6. Working Temperature: -10C to 80C Bluetooth 4.2 and BLE

- 7. Analog I/O pins— 12 CHANNELS (reconfigurable)

- 8. Built-in Hall effect and Temperature sensor

- 9. PT 100 Precision temperature measurements upto 6 Nos

- 10. Modbus-based energy meter interface upto two energy meters (Elmeasure Make)

- 11. MEMS accelerometer Connection interface CbM

Machine tool condition monitoring (MTCM) EDGE module will be cost-effective and affordable.

Simple IoT Application & Kits

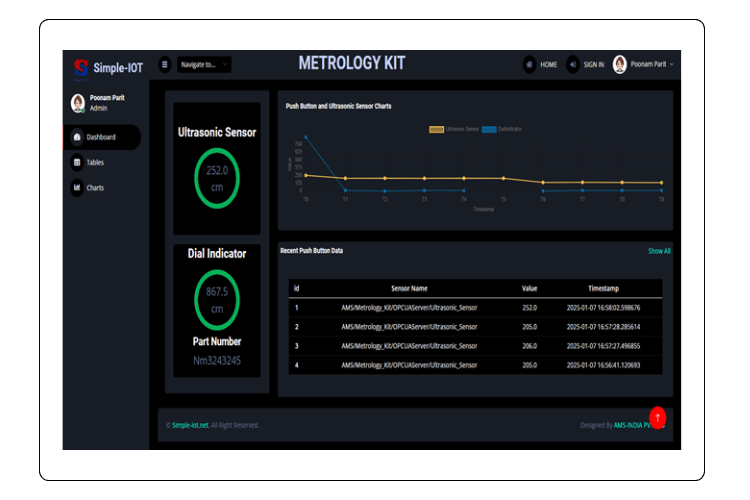

SimpleIOT is a cutting-edge mobile application developed by Advance Mechanical Services, designed to revolutionize industrial sensor monitoring and data management. Our solution transforms raw sensor data into actionable insights, enabling industries to enhance their operational efficiency and decision-making processes.

Key Benefits

- Real-time sensor data monitoring

- Intuitive data visualization

- Advanced reporting capabilities

- Multi-kit sensor integration

- Flexible configuration options

Core Features

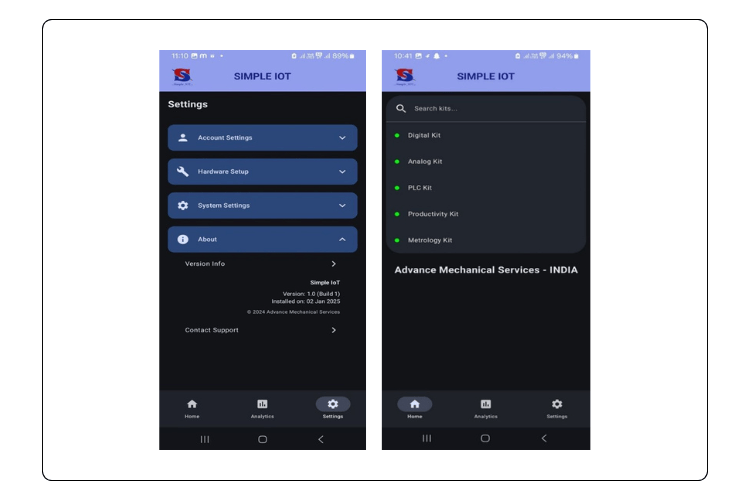

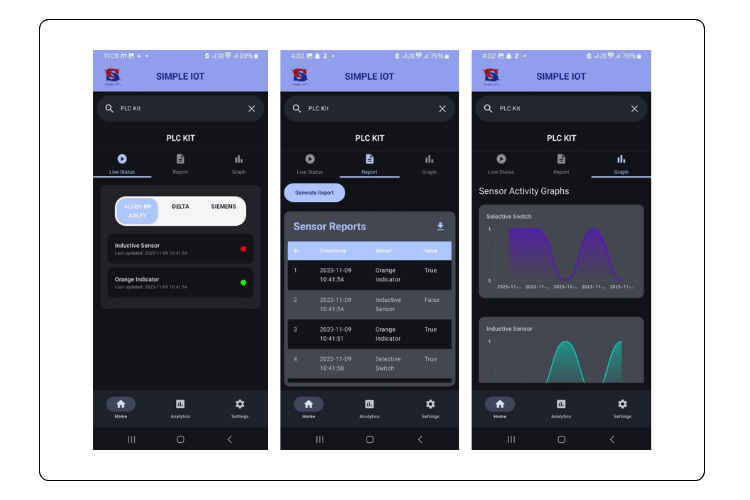

Home Screen Features

- Search functionality

- Real-time kit connection status (online or offline)

- Kit selection mechanism

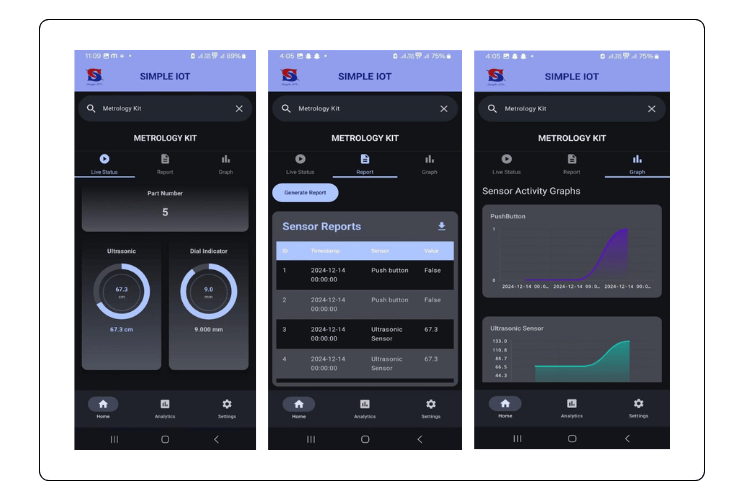

Kit Monitoring Screens

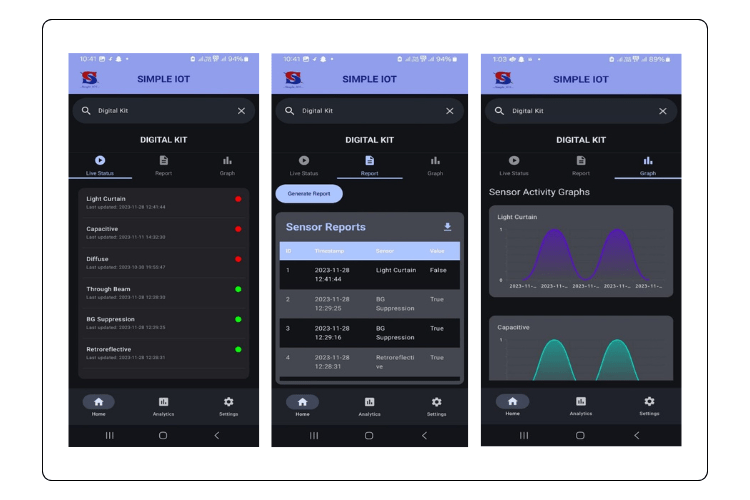

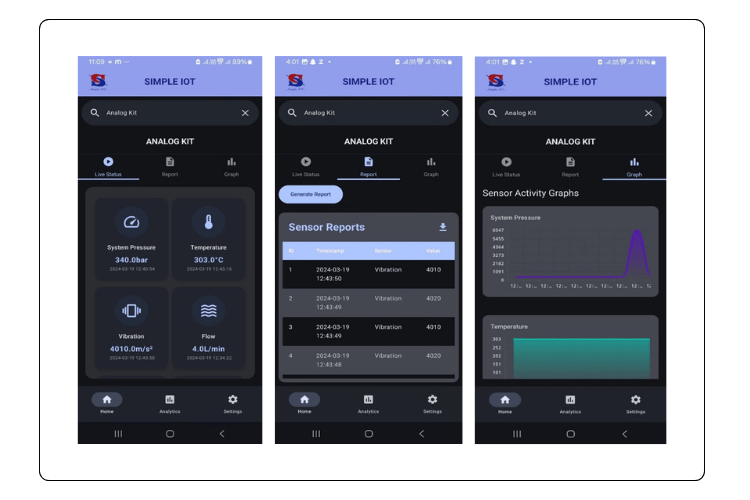

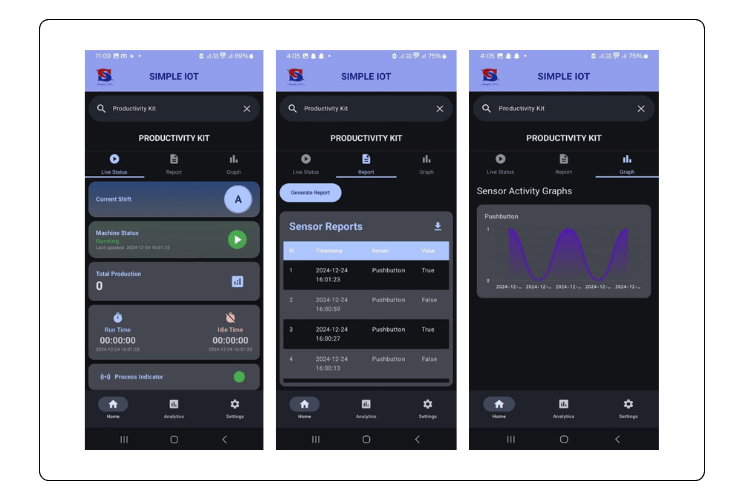

Live Status Tab

- Real-time sensor readings

- Instantaneous machine status

- Performance metrics visualization

- Color-coded status indicators

Reporting Tab

- Customizable time-range selection

- Comprehensive data filtering

- CSV export functionality

- Local storage options

Graphical Analysis Tab

- Last 10 sensor value trends with Timestamp annotations

- Interactive graph interfaces

- Zoom and scroll capabilities

Simple IoT Kits

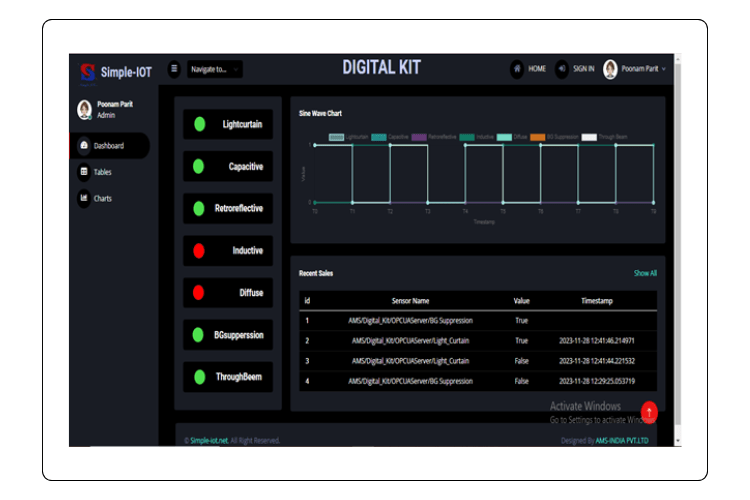

Digital Kit

- High-precision digital signal processing

- Binary state monitoring

- Rapid data transmission

Sensors Connected

- Light Curtain

- Capacitive

- Diffuse

- BG Suppression

- Through Beam

- Retro Reflective

- Inductive

Ideal for

- Robotic Handling and Quality Control

- Sorting, Packaging, and Safety

- Assembly Line Monitoring and Safety

- Elevator Door Positioning and Safety

- Guided Vehicle Navigation and Object Avoidance

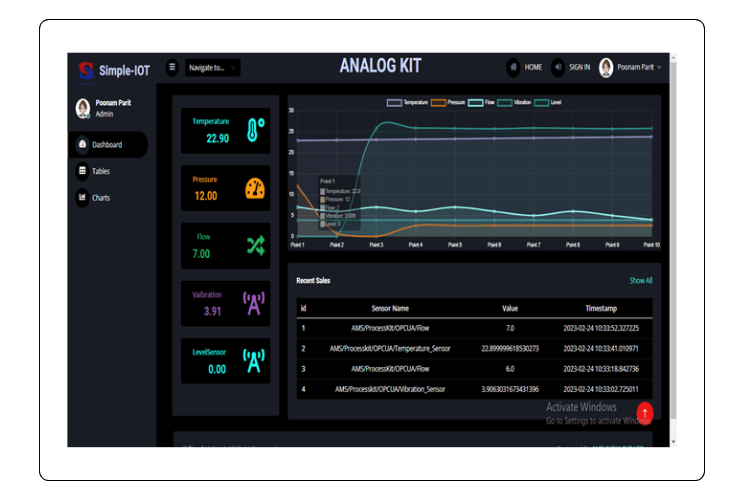

Analog Sensor Kit

- Continuous signal measurement

- Wide range of input types

- Precise analog value tracking

Sensors Connected

- Pressure

- Temperature

- Flow

- Level

- Vibration

Ideal for

- Oil Pump Monitoring in Oil & Gas Industry

- HVAC Compressor Protection

- Power Plant Turbine Lubrication Monitoring

- Hydraulic System Monitoring in Marine

- Industrial System Monitoring in Manufacturing

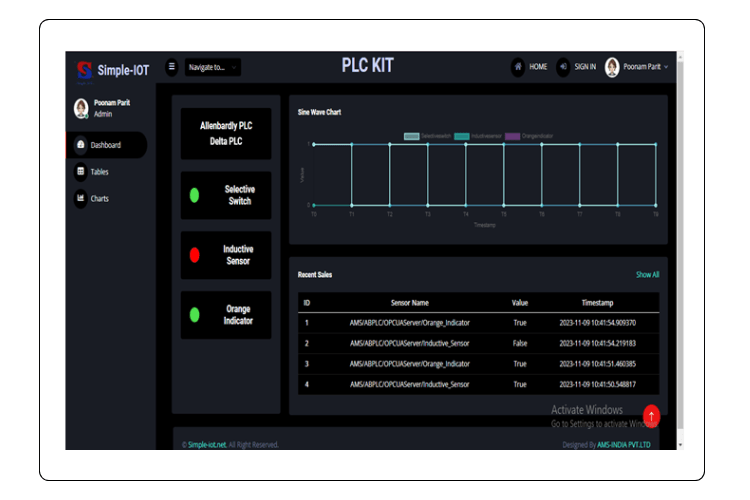

PLC Kit

- Industrial automation monitoring

- Complex logic interpretation

- Machine control interface

PLC Connected

- Allen-Bradley

- Delta

- Siemens

Ideal for

- Multi-Machine Control System

- Batch Mixing System

- Solar Power Plant Monitoring and Control

- Vehicle Cleaning and Drying

- Test Bench Automation

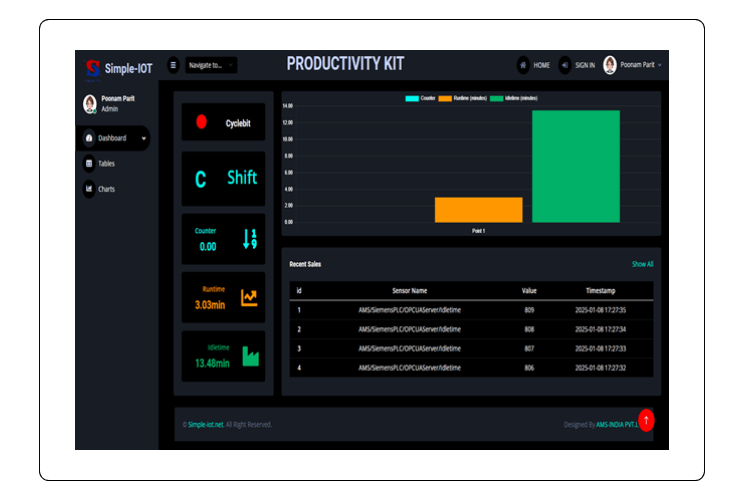

Productivity Monitoring Kit

- Production line performance tracking

- Efficiency measurement

- Downtime analysis

- Shift wise data processing

PLC Connected

- Siemens

Ideal for

- Real-time Manufacturing Performance Monitoring

- Tracking Productivity and Identifying Bottlenecks

- Energy Efficiency and Cost Reduction

- Downtime Analysis and Maintenance Planning

- Production Scheduling and Capacity Planning (Planning and Scheduling Future Shifts)

- Quality Control and Defect Tracking

- Labor Productivity Analysis (Workforce Performance Tracking)

Productivity Monitoring Kit

- Precised measurement tracking

- Quality control integration

- Dimensional analysis support

Sensor Connected

- Barcode Scanner

- Ultrasonic Sensor

- Dial Indicator

Ideal for

- Part Quality Control and Inspection

- Automated Part Sorting and Rejection

- Precision Measurement in Aerospace and Automotive Manufacturing

- In-Process Measurement for CNC Machining

- Verification of Precision Parts in Electronics Manufacturing