Advance Mechanical Services helps Academia-Industry connect through the establishment of Center of Excellence (CoE) through collaborative effort involving leading Industry players.

The aim is to set up the Centre of Excellence with Internationally renowned Industry-Grade Solutions related to Robotics, AI-ML, IOT, Digital Manufacturing and Additive Manufacturing so that the faculty and students of the Institution develop competencies related to high-quality careers, research, innovation, and consultancy projects in above domain. The CoE serves as a LAB for real time applications used in the Industry.

AMS-INDIA curated ensemble of hardware and software components.

In today’s rapidly advancing industrial landscape, integrating Artificial Intelligence (AI) and Machine Learning (ML) technologies has become paramount for enhancing manufacturing efficiency, productivity, and precision. With a focus on educational applications, we present an innovative AI and ML Kit designed to revolutionize the teaching and learning experience in automation and robotics.

The AI & ML Kit encompasses a comprehensive array of components crafted to provide hands-on experience and practical insights into automation, robotics, computer vision, and intelligent decision- making algorithms. This kit is meticulously engineered to offer a holistic learning platform, enabling students and professionals to delve deep into the intricacies of modern automation systems.

This curated ensemble of hardware and software components empowers learners to explore concepts such as object recognition, classification, sorting, and decision-making algorithms within a controlled yet realistic industrial environment. Whether it’s understanding the intricacies of robotic manipulation or harnessing the power of AI-driven decision-making, our AI & ML Kit provides the perfect platform for immersive learning and experimentation.

Applications

- Material handling

- Machine tending

- Spot welding

- Arc welding

- Cutting

- Assembling

- Testing

- Inspecting

- Dispensing

- Grinding

- Polishing

| Sl. No | Items | Specifications |

| 1 | Industry Grade Robot of ABB (1 unit) |

Model: ABB-IRB 1200 | Handling Capacity: 5 Kg Reach: 0.9 m | DOF: 6 | Weight: 54 Kg Power Consumption: 0.45 kW |

| 2 | Vision System |

Model: HIK Vision | System Hardware: 1.3 MP Camera Lens: 150 x 120 mm FOV | Light: 140 x 140 mm FOV |

| 3 | Soft Robotic Grippers |

Types: Mini (Max Load: 10 gm) | Light (Max Load: 270 gm) Medium (Max Load: 540 gm) | Heavy (Max Load: 600 gm) |

| 4 | Load Station | Dimension: 30 x 25 cm | Payload: 5 Kg |

| 5 | Conveyor |

Distance: 600 mm | Speed: 120 mm/sec | Payload: 500 gm Dimension: 700 x 215 x 60 mm | Net weight: 4.2 kg |

| 6 | Segregation Bins & Inspection Bins | Dimension: 296 x 225 x 140 mm | Material: Sheet Metal |

| 7 | AI & ML Software | ABB Robot Studio & Deep Learning Software |

| 8 | Vacuum/Pressure Pump |

Model: iPCU2-SMN | Output Pressure: -90 to 300 Kpa Lifetime: 50 Million Times | Working Noise: 50 db Air source: 0.45 – 0.80 MPa, dry, clean | Stable Flow: 200 L/min Size: 208 x 134 x 141 mm |

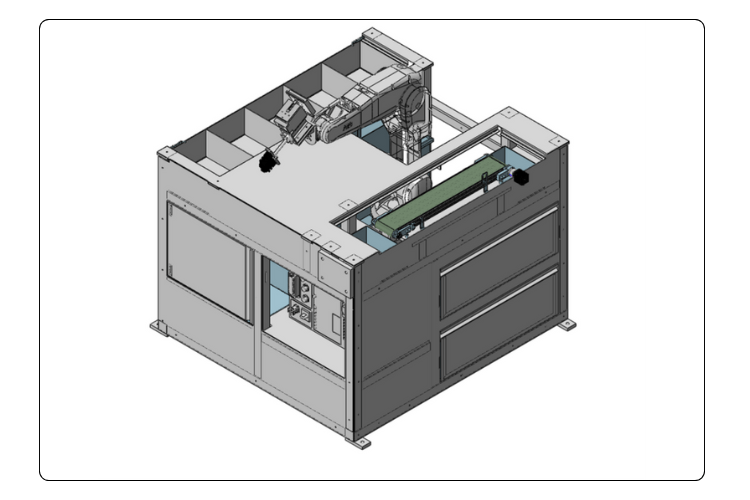

| 9 | Integrated Cell | Dimension: 1 m x 1 m |

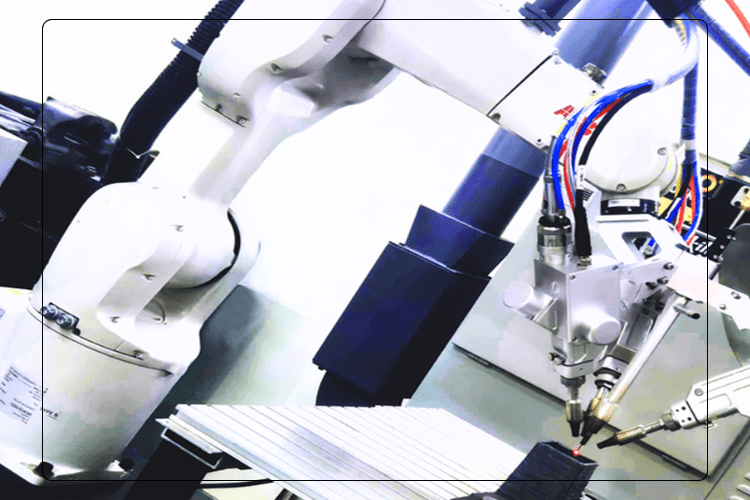

AMS-INDIA designed Robotic – Laser Wire Additive Manufacturing (LWAM) machine with our patented three Laser Head system.

About Robotic LWAM Cell

Laser Wire Arc Additive Manufacturing (LWAM) is an additive manufacturing process that utilizes a laser arc as the heat source to melt a metal wire, which is deposited layer by layer to build up a 3D object. It is commonly used for producing metal parts in aerospace, military and automobile industries.

The LWAM Robotic Cell combines the robustness and agility of the ABB IRB-1200 Robot with the advanced capabilities of Robot Studio software, providing users with intuitive control and seamless integration for precise and efficient operation integrated with a unique patented Laser Head which focuses a maximum of 4.5KW of Laser energy to melt the metal and a wire feeder to deposit the wire in a pre-programmed path to make components.

Paired with the powerful laser and a wire feeder, this system empowers users to achieve unparalleled weld quality and deposition rates in additive manufacturing applications.

Advantages of Robotic LWAM Cell

- Provides outstanding performance by utilizing ABB’s superior path performance and Absolute Accuracy calibration

- Robot’s close motion coordination with an external axis

- Seamless integration with the robot controller and suitable welding equipment

- High power laser, energy efficiency and consistent performance.

- Advanced technology reduces defects and post-weld processing.

- Flexible setup for different materials and welding techniques.

- Robust design suitable for industrial environments.

- Cost-Effective: Compared to other additive manufacturing methods, LWAM uses inexpensive materials and equipment, making it a more affordable solution for large-scale parts.

- High Material Utilization: LWAM offers high material efficiency because it uses a wire feed, minimizing waste compared to powder-based methods.

- Scalability: It is suitable for producing large parts, unlike many other AM processes that are restricted to smaller components.

- Versatility in Materials: LWAM can handle a wide range of metals, making it highly adaptable for various industries.

- Reduced Lead Time: Large parts can be manufactured much faster than traditional machining methods.

Key Components of LWAM:

- 1. Wire Feedstock:An open source metal wire, typically made of materials like, aluminium, steel, or Inconel, is used as the raw material for the process.

- 2. Laser: 4.5KW Laser power source generates the Laser, fed to the metal through a laser gun is used to melt the wire.

- 3. Movement System: The wire feedstock and the arc are fed through a patented head which is precisely controlled in all axes by robotic arms to form the part layer by layer.

- 4. Cooling: The water chiller Unit of 6KW is used to cool the laser power source and the laser heads for continuous operation.

Applications

- Aerospace: Manufacturing complex, lightweight structures like brackets, frames, or engine components.

- Marine: Producing large, durable parts that can withstand harsh environments.

- Automotive: Creating high-strength components with intricate geometries.

- Tooling: Fabricating large custom tools and dies for industrial use.

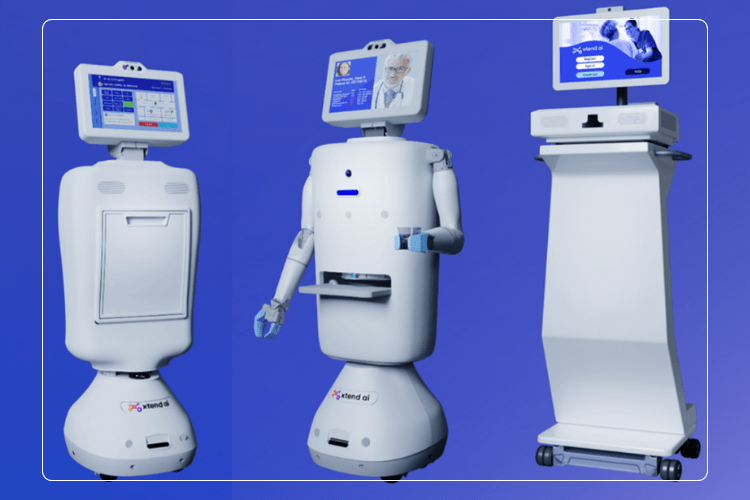

AMR customised with Interactive Avatars

Our mission has been to develop affordable, customizable, and upgradeable intelligent autonomous robots that address the specific needs of each industry and sector, resulting in immediate integration in the workplace. The “Local” offline AI engine enables the robots to operate without connectivity to the internet or cloud, enabling them to Work Offline.

Students at the Institute can develop applications, test and implement in Industry/Service sectors.

Curated Applications

- Healthcare (Intelligent Medical Kiosks)

- Education (Virtual Tutors)

INDUSTRIAL INTERNET OF THINGS (IIOT)

| Sl. No | Items | Details / Use / Relevance |

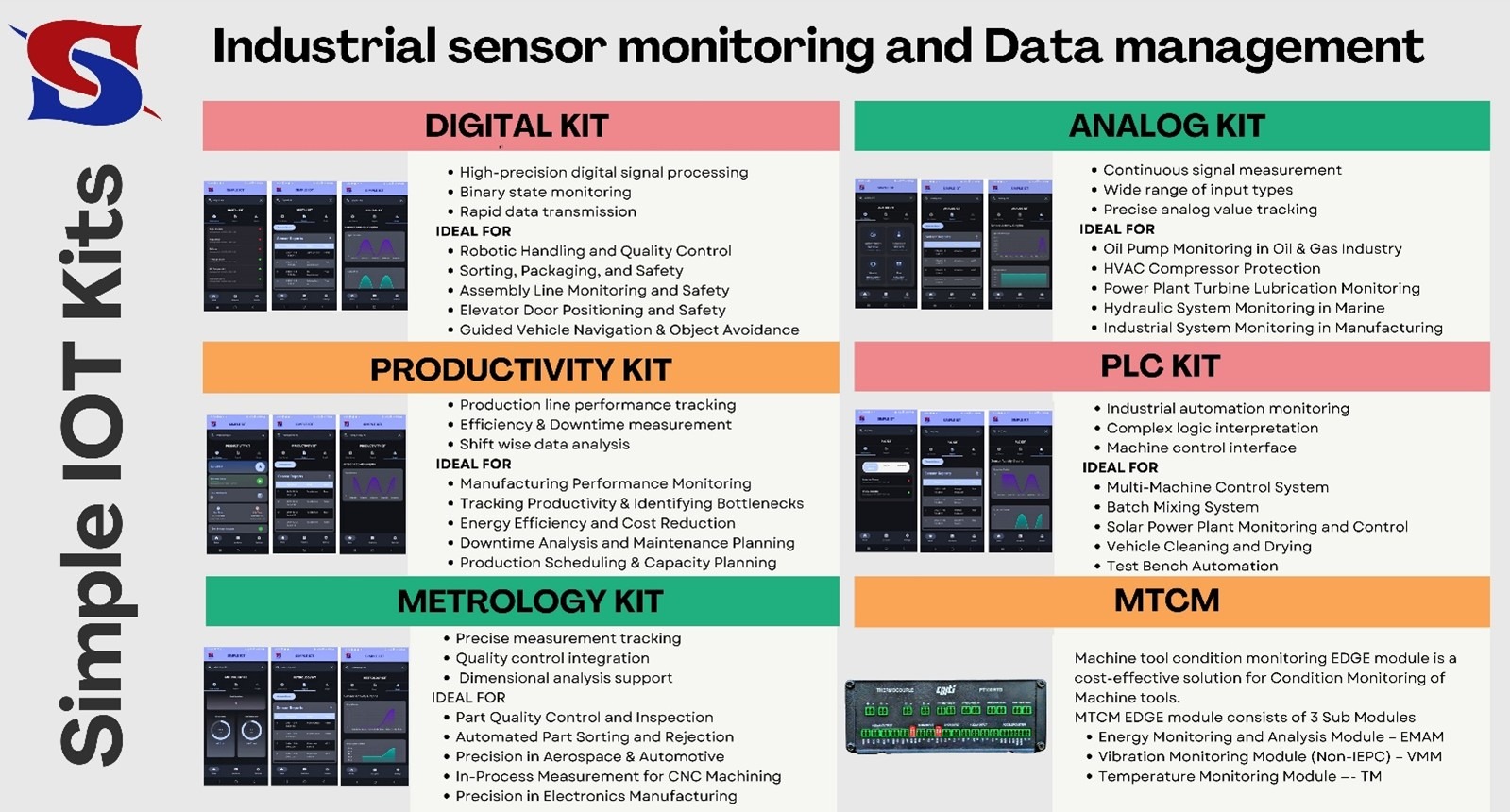

| 1 | Digital Kit | The Digital Kit is an advanced sensor and control system designed for Ethernet operation. It smoothly incorporates various sensors, such as the Inductive Sensor, Through-Beam Sensor, Retroreflective Sensor, Diffuse Sensor, Background Suppression Sensor, Capacitive Sensor, and Light Curtain Sensor. The ATOP Control intricately links with the digital signals from these sensors. |

| 2 | Analog Kit | The Analog Kit functions as an integrated sensor and control system operating over Ethernet. It combines signals from Vibration, Level, and Temperature Sensors with DI and AI inputs through the AIO Controller. Utilizing the Ewon Flex Gateway and the Modbus TCP Protocol, the system ensures efficient data transmission over Ethernet for seamless integration and monitoring. |

| 3 | Productivity Kit |

The Productivity Kit integrates sensors and controls. The Delta PLC Controller manages signals from pushbuttons and indicators. Data transmission occurs via the Modbus RTU protocol over RS232 without the need for additional hardware like a gateway. |

| 4 | Metrology Kit | The Checking Fixture Kit, integrated with IIoT (Industrial Internet of Things), fosters heightened connectivity for businesses and individuals with the world around them. This advanced level of connectivity facilitates more meaningful and sophisticated tasks, empowering users to engage in higher-level work specifically within the domain of checking fixtures. |

| 5 | PLC Kit | The PLC Kit is a sophisticated sensor and control system designed for RS232 connectivity. It seamlessly integrates Delta PLC Controller, combining Digital Input (DI) and Analog Inputs (AI) signals derived from Toggle switch, Diffuse sensor, Indicator and Potentiometer. Data transmission is facilitated through RS232 using the Modbus RTU Protocol, with an OPCUA server Gateway serving as the interface for seamless communication. |

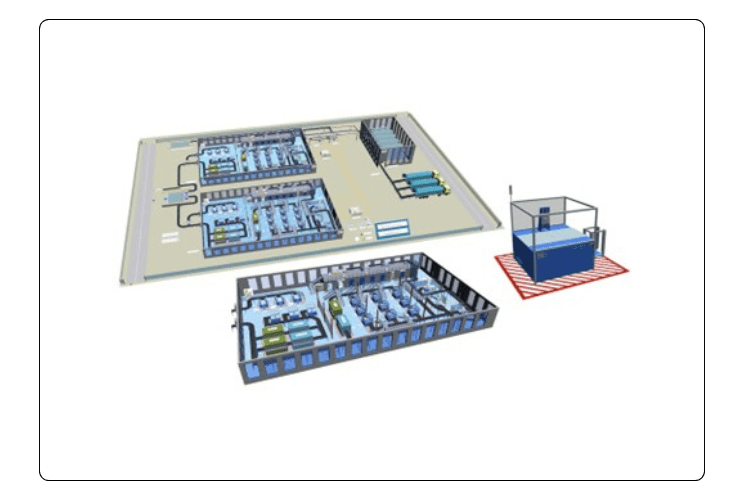

DIGITAL MANUFACTURING

Digitalize manufacturing and the process for turning your innovative ideas—from vehicles, aircraft and machinery to medical devices, electronics and consumer goods—into products. Plant Simulation software enables you to model, simulate, visualize and analyze production systems and logistics processes to optimize material flow and resource utilization for specific production lines.

Plant Simulation X Essentials is a powerful, entry-level digital manufacturing solution that features core statistical simulation capabilities to create, analyze and optimize 3D models of production systems and their processes using basic objects, user-defined objects, libraries and controls for up to 500 objects.

Key features

- Simulate, validate and optimize Create 3D visualization models up to 500 objects in size for simulation, validation and optimization of your production systems and processes using Plant Simulation Essentials software. Optimize material flow, resource utilization and logistics for all levels of plant planning—from global production facilities and local plants to specific lines.

- Explore and analyze Accurately model logistics and production systems to explore their characteristics and optimize their performance. The digital model enables you to run experiments and what-if scenarios without disturbing your existing production system or—when used in the planning process—long before the real system is installed. Extensive analysis tools, statistics and charts let you evaluate different manufacturing scenarios and make fast, reliable decisions in the early stages of production planning. Validate part routing and gain a comprehensive view of machine states, facilitating better decision-making and production management.

- Streamline data exchangeLeverage integration with technologies like ActiveX, C-Interface, MQTT, ODBC, OPC UA, PLCSIM Advanced, SIMIT, SQL for Oracle, and Socket to enable direct access to third-party code, database integration, and efficient data transfer, enhancing real-time simulation and monitoring.

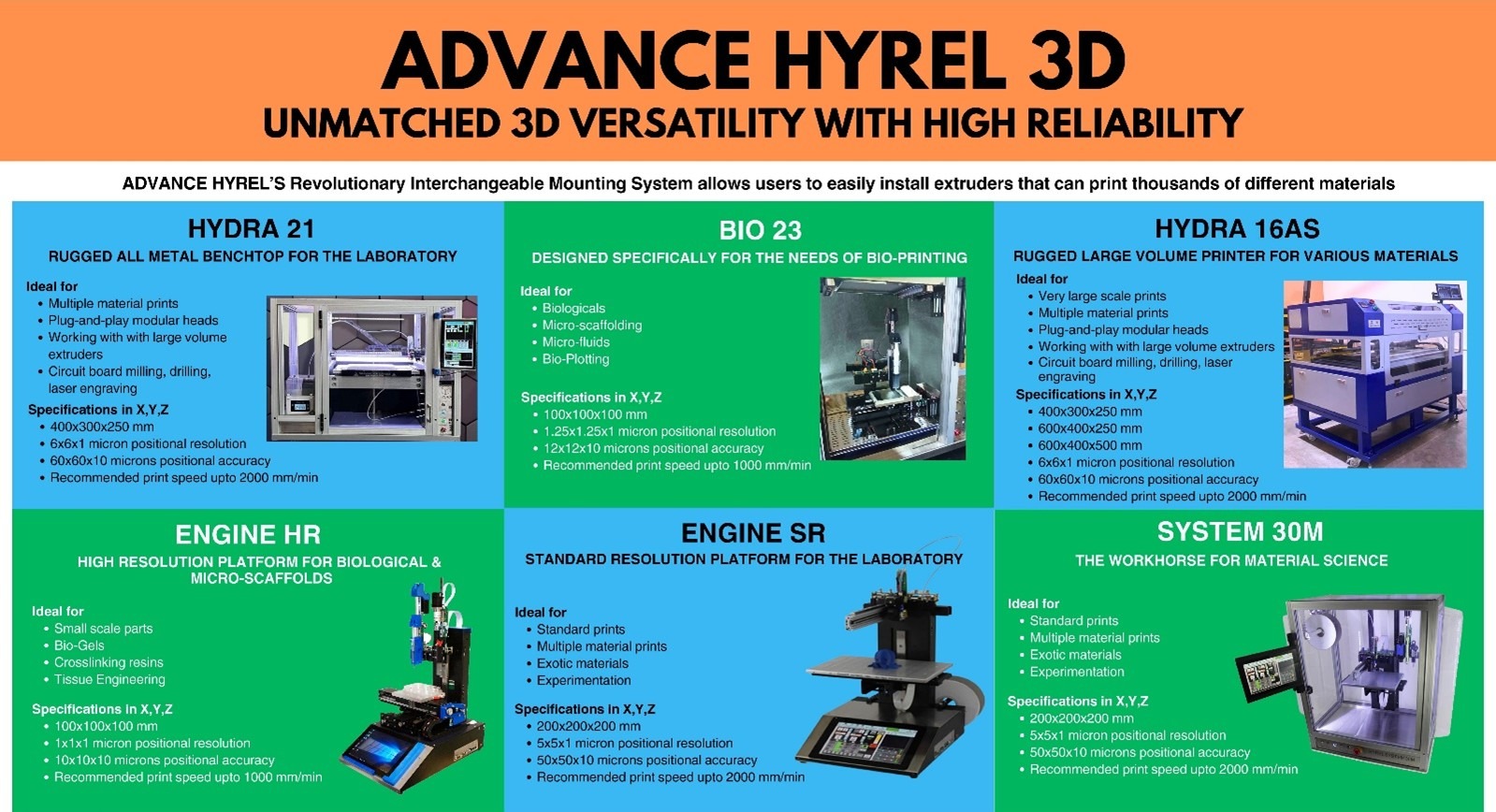

ADDITIVE MANUFACTURING

AMS-India has collaborated with Hyrel 3D Inc of USA to manufacture a range of 3D Printers. The vision of the company is to become a world-class Center of Excellence for research & development using 3D Printing machines. ADVANCE HYREL’S revolutionary Interchangeable Mounting System allows users to easily install extruders that can print thousands of different materials, which is useful for research purposes.

AMS-India is continuously working with many top-class Indian Universities and Institutions in additive manufacturing and is collaborating with Indian Institute of Science, Bangalore for the development of new techniques in AM.

ARTIFICICIAL INTELLIGENCE (AI)

AI IN EDUCATION

AMS-India will deliver personalized learning experiences with AI-driven educational technologies that adapt to individual student needs, improve engagement, and enhance learning outcomes.

- Adaptive learning platforms

- Intelligent tutoring systems

- Personalized curriculum recommendations

- Advanced learning analytics

AI ENGINE System Architecture & Features

Innovative AI-powered learning companions (Avatars) that provide personalized, interactive educational experiences tailored to individual learning styles.

- 1. Large Language Model (LLM) Integration

- 2. Multi-Threaded Processing System

- 3. Dynamic Content Adaptation

- 4. Educational Level Recognition

- 5. Context-Aware Learning

- 6. Smart Content Structuring

AI TUTOR Core Technologies & Features

- 1. Voice Recognition Technology

- 2. LLM-Based Content Processing

- 3. Real-Time Speech Synthesis

- 4. Dynamic Content Adaptation

- 5. Level-Specific Learning Algorithms

AI PDF Core Technologies & Features

- 1. Advanced PDF Analysis Tool

- 2. Powered by LLM Technology

- 3. Built with Python & PyQt5 Framework

- 4. Modern and User-Friendly Interface

- 5. Real-Time Analysis Capabilities

- 6. Professional Result Generation